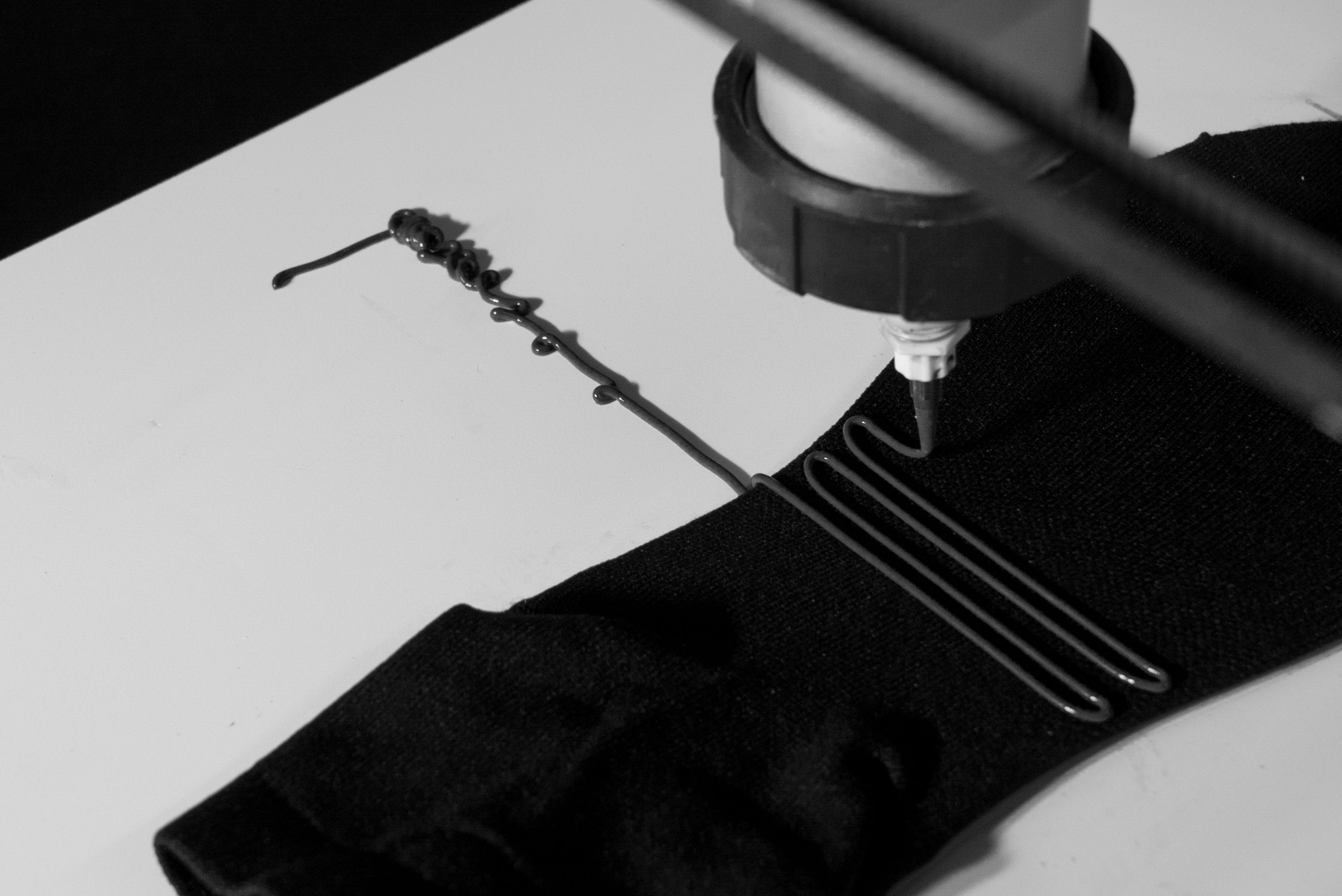

In this project we research on further application potentials of the structure printing technology GRDXKN and technical possibilities of implementation. The printing technology gives the textil through its colour a body, a shape and thus brings with it new properties such as abrasion resistance, slip resistance, water repellency, upholstery and textile stabilisation. In addition, the printed pattern is plastically reproduced on the reverse side of the fabric.The ink is applied to the textile using a stencil printing process. Through temprature the ink bonds firmly with the textile and gains volume. Our material research results in three new application potentials: a jacket with soft protection, a 3D printed sole for a sock shoe and a carpet. The jacket is an everyday protective jacket for cyclists in the city. The different density of the pattern adapts to the individual body shape and makes a comfortable movement possible. A special focus of this project is the use of rapid prototyping technologies in combination with GRDXKN. Numerous tests, test arrangements and prototypes have been developed for this purpose. The 3D printer serves as a threedimensional drawing tool. The sole is printed directly on the sock, which is stretched over a last.

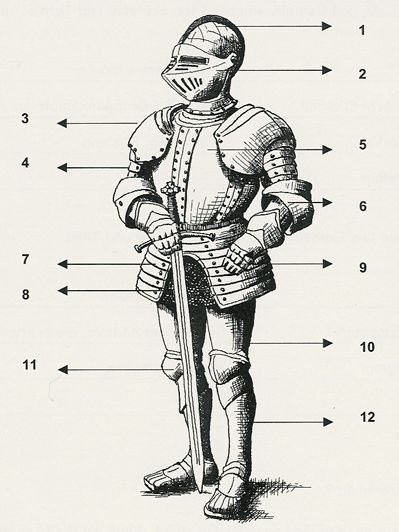

- FF.1: Research knight's armor

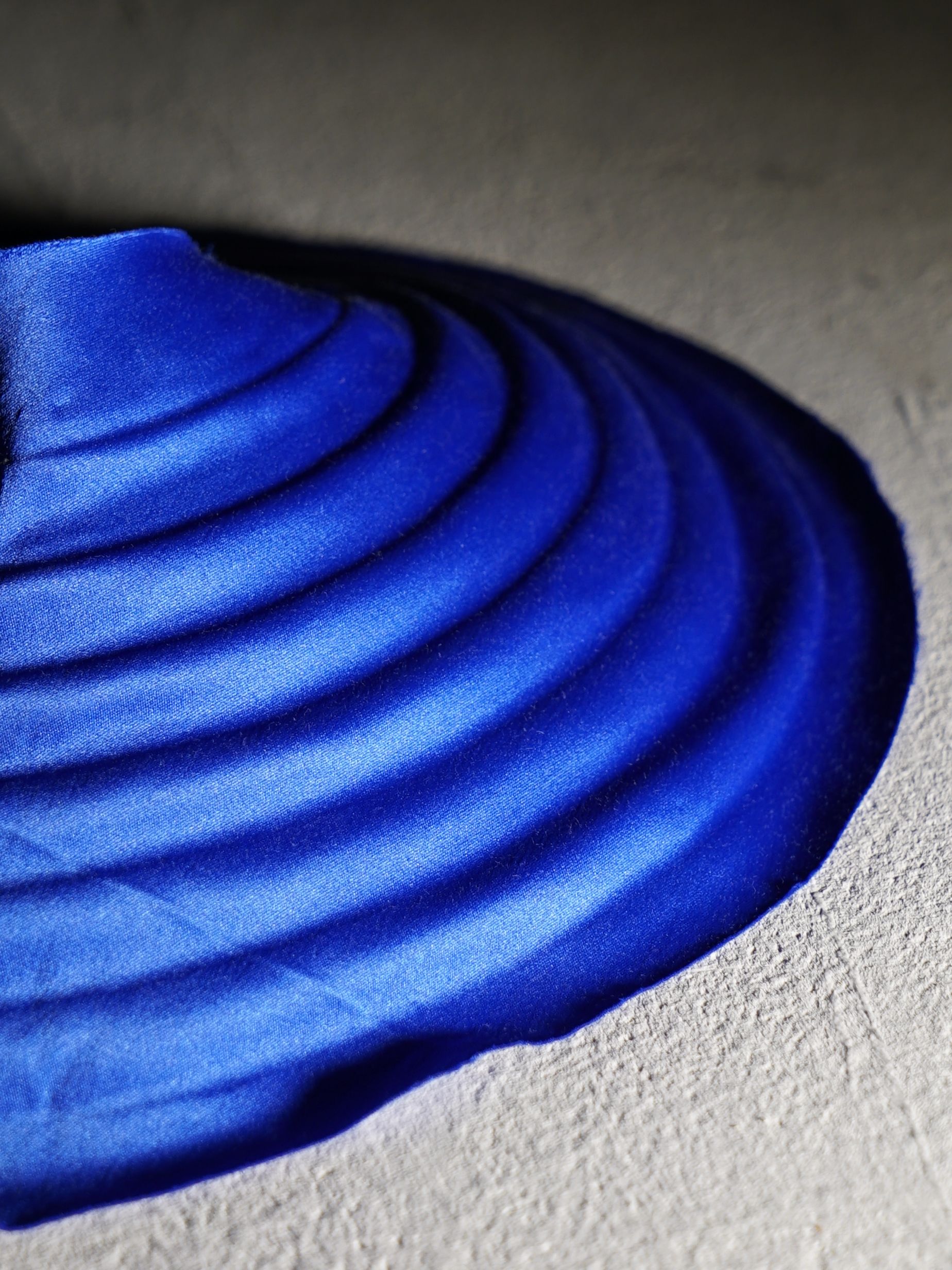

- FF.2: Material experiments soft protection jacket

- FF.3: Material experiments soft protection jacket

- FF.4: Detail soft protection jacket

- FF.5: Detail soft protection jacket

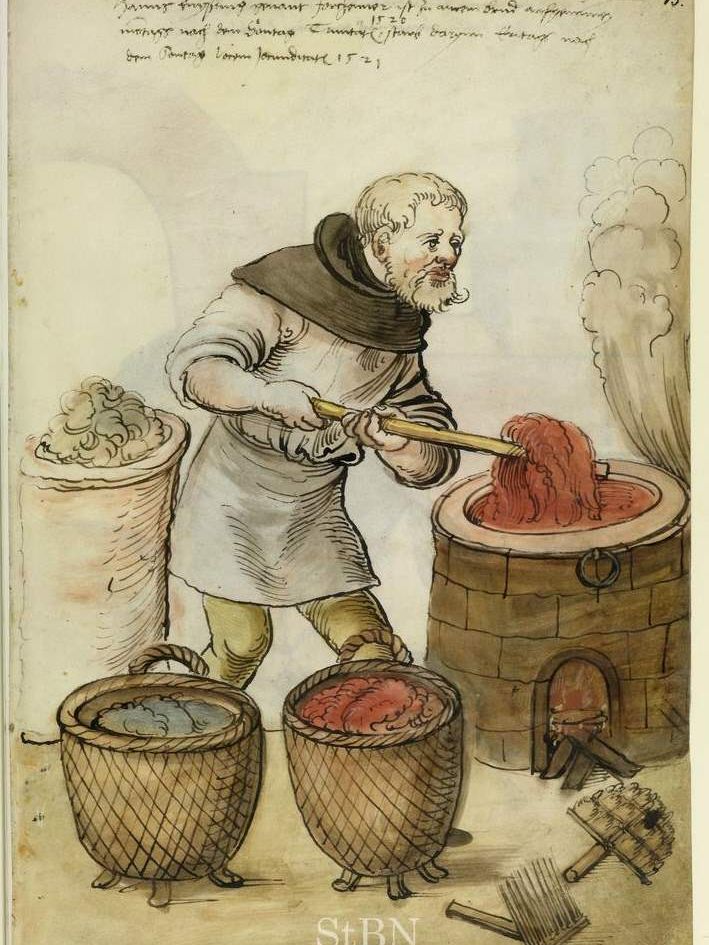

- FF.7: Dying process

- FF.8:

- FF.9:

- FF.11:

- FF.12: